Aluminium Alloy Extrusion Profile CNC Machining Accessories for Bicycle Rear Seat

1) Company Introduction:ALUMAG ALUMINIUM TECH (TAICANG) CO. LTD. was established in May, 2002 as a Taiwanese invested in

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | 6061 |

| Surface Finishing | Customized |

| Alloying Ingredient | 6061 |

| Certification | ISO |

| Polished Aluminum Profile | OEM |

| Deep Process | CNC Machining |

| Finish Treatment | Anodizing/Powder Coated |

| MOQ | 300kgs |

| Inspection | Calipers,CMM,Projector |

| Size | OEM,Range From 4 to 270mm |

| Payment Terms | 30%Tt Deposit,70%Balance Against Bl Copy |

| Delivery Time | 10-15days |

| Transport Package | Plastic Bag Kraft Carton Wooden Box as to Custome |

| Specification | customized |

| Trademark | Alumag |

| Origin | Jiangsu, China |

| HS Code | 7604299000 |

| Production Capacity | 1000-1500 Tons Per Month |

Product Description

1) Company Introduction:ALUMAG ALUMINIUM TECH (TAICANG) CO. LTD. was established in May, 2002 as a Taiwanese invested industry, ALUMAG (TAICANG) is located in Tai Cang Port, Tai Cang City, Jiang Su Province;having a profession of producing many kinds of Aluminum Alloy extrusion products, which have been widely used in Auto Parts and Bicycle Components, Pram Fittings, Medical Facilities, Sports Equipment, Furniture and Heat Sinks etc.ALUMAG (TAICANG) owns the strong technical skills and production lines. The products are made according to customer's requirements on technological parameters and sizes;It has been honored by ISO9001:2015 , IATF16949:2016 Quality Assurance Control Request - Auto Industrial Special Request for years and also the ISO 14001:2015 Environmental management systems.ALUMAG has built up a great management and a professional team providing our customers toward the best products and services.2) Our referenced products:

3)Our Production Ranges:

| Material | 1050 1060 1100 2014 3003 5052 6061,6063 7075 etc |

| Temper | O-H112 T3-T8 |

| Surface treatment | Mill Finish,Anodized,Eletropharesis,Powder Coated, Paiting,Polish,Sandblasting,brushed |

| Length | 0.3mm-6.2mm |

| Shape | Round,Square,Rectangle,Triangle,Hexagon,Octagon,Oval,or as per the drawings and samples |

| Deep Process | cutting,drilling,punching,milling,deburring,clearing,tapping etc |

| Wall thickness | > 0.3mm |

| Section size | Square: ≤ 150*150mm Rectangle:≤ 250*50mm Round: ≤ ∅170mm |

| Package | inner plastic paper interleaving each tube,outer fixed by plywood or pallets,or as required |

| Delivery time | 15-25 days after deposit |

| Certification | ISO9001,IATF(ISO/TS)16949, ISO14001 |

| Aluminium Alloy Chemical Composition | ||||

| Alloy | 6063 (%) | 6063A (%) | 6061 (%) | 6082 (%) |

| Si | 0.2~0.60 | 0.3~0.60 | 0.4~0.80 | 0.7~1.30 |

| Fe | 0.35 | 0.15~0.35 | 0.70 | 0.50 |

| Cu | 0.10 | 0.10 | 0.15~0.40 | 0.10 |

| Mn | 0.10 | 0.15 | 0.15 | 0.40~1.0 |

| Mg | 0.45~0.90 | 0.60~0.90 | 0.80~1.20 | 0.6~1.20 |

| Cr | 0.10 | 0.05 | 0.04~0.35 | 0.25 |

| Zn | 0.10 | 0.15 | 0.25 | 0.20 |

| Ti | 0.10 | 0.10 | 0.15 | 0.10 |

| Other (each) | 0.05 | 0.05 | 0.05 | 0.50 |

| Other (total) | 0.15 | 0.15 | 0.15 | 0.15 |

| Al | Remainder | Remainder | Remainder | Remainder |

Welocme to visit Alumag!

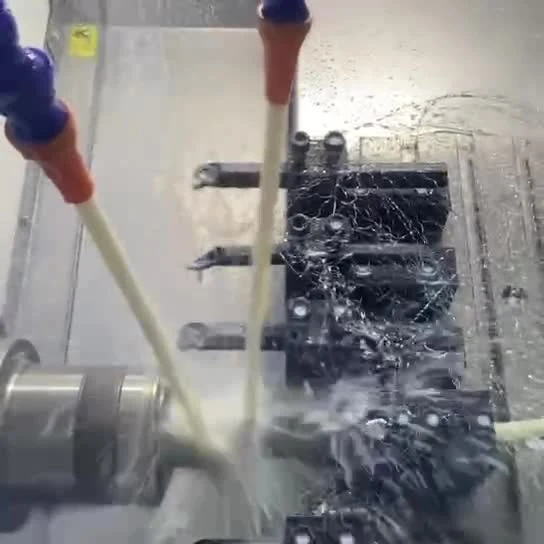

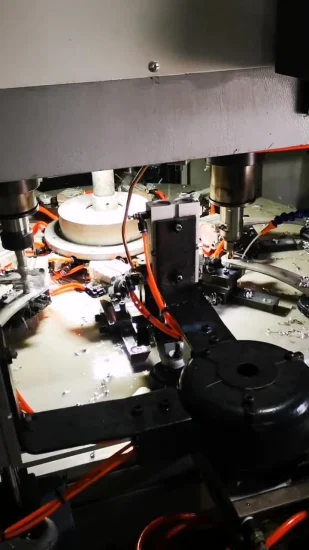

5) Our Production Facilities:

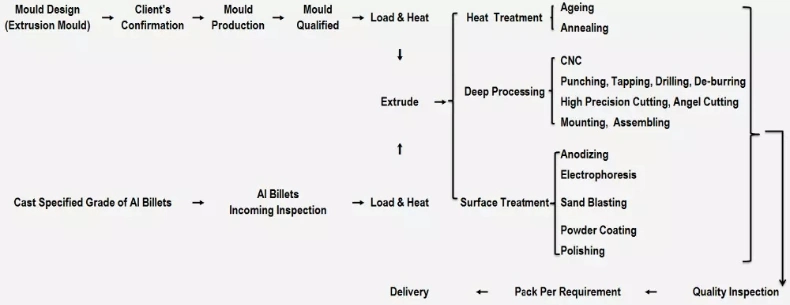

6)Production Flow:

7)Our workshops:

8)Our Inspection labs:

9)Packages&Shipping:

10) FAQ:

1. Are you a manufacture or trading company?

We are a Taiwanese invested factory. We have one factory in Taicang, Jiangsu province, producing aluminum alloy products and the other one in Taiwan producing magnesium alloys.

2. What are your main products?

Our main products are Aluminum /Magnesium extruded products and processed accessories. We also assemble finished products according to customer's need.

3. What is the application of your profile of aluminum extrusion?

Our industrial aluminum profile extrusion can be widely used in many fields such as: auto parts, electronic components, medical facilities, sports equipment, Furniture spare parts, cake mould and other industrial applications.

4. What kind of deep process you can provide?

We have CNC machine Centers, drilling machines, Lathes, Drawing Machine, Angle Cutting Machine, Miller, Punching Machines, High Precision Automatic Cutting Machines, Strengthening machine ect.

5. Do you provide OEM and ODM service?

Yes, we provide customized service.

6. What is your minimum order quantity (MOQ)?

Our MOQ is normally 300kgs. For large section size,MOQ will be 2 Tons.

7. Can you do special alloys?

Yes, we can produce high alloys and special alloys. We also do Magnesium alloys.

8. How can you assure your quality?

We have advanced equipment to analyze and test in each production stage.

We will issue quality assurance certificate for each shipment.

9. Why choose Alumag?

1) Alumag has a best Technical Team, which has 20~30 years industrial experience; Medium Administrative staffs have over 10 years professional experience.

2) Our extruders and testing equipments were all imported from Taiwan, Japan, Germany and etc.

3) We can ship our goods from our Taiwan factory which may help you avoid high import taxes.

Related Products

-

![Bilateral Lock Training Mountain Riding Equipment Bicycle Anti Slip Handle Bar Grip Cover Cycling Rubber Vice]()

Bilateral Lock Training Mountain Riding Equipment Bicycle Anti Slip Handle Bar Grip Cover Cycling Rubber Vice

-

![OEM Aluminum Alloy 170mm MTB Bike Bicycle Crank Crankset]()

OEM Aluminum Alloy 170mm MTB Bike Bicycle Crank Crankset

-

![Hot Sell Chinese Bicycle Crank Arm 52t Track Parts Bike Single Speed Crankset]()

Hot Sell Chinese Bicycle Crank Arm 52t Track Parts Bike Single Speed Crankset

-

![Wholesale Sport Saddle for Junior Bicycle MTB Kids Mountain Bike Seat]()

Wholesale Sport Saddle for Junior Bicycle MTB Kids Mountain Bike Seat